Vodka

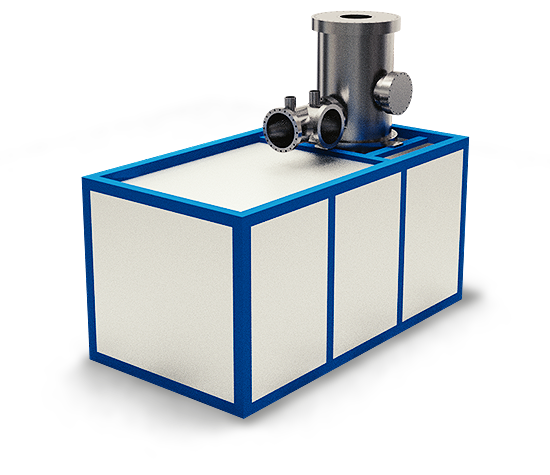

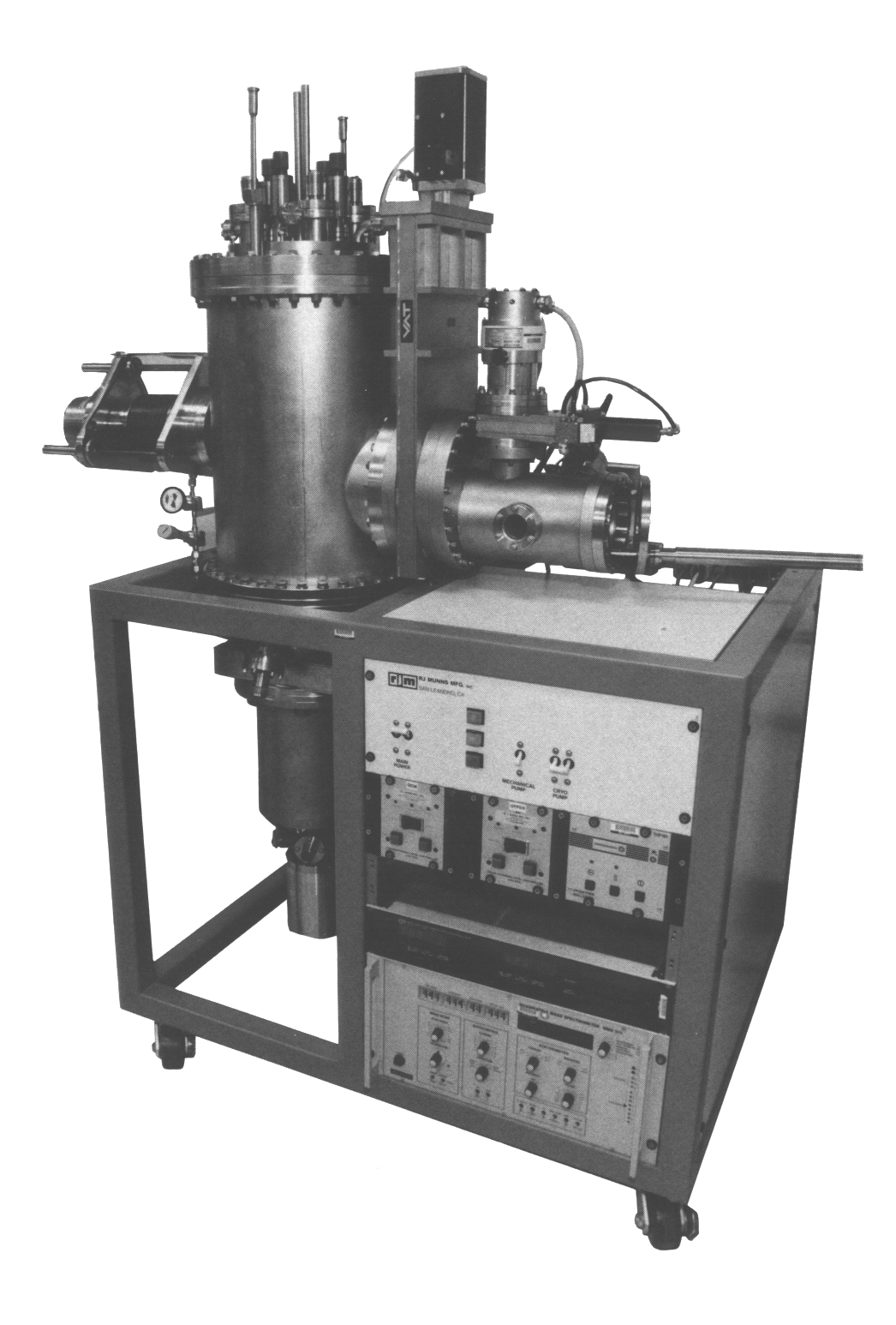

Vacuum Outgassing Deposition Kinetics Apparatus.

The essential components of the VODKA are QCM sensors and an effusion cell, in which you can heat any material (eg. adhesives and sealants, cable insulation and shrink tubing, conformal coatings, electrical components, electrical shields, films and sheet materials, foams, grease, lubricants, liquids, lacing tape and cord cable ties, laminates and circuit boards,

The essential components of the VODKA are QCM sensors and an effusion cell, in which you can heat any material (eg. adhesives and sealants, cable insulation and shrink tubing, conformal coatings, electrical components, electrical shields, films and sheet materials, foams, grease, lubricants, liquids, lacing tape and cord cable ties, laminates and circuit boards,

Introducing

Predicts: Outgassing and Deposition Kinetics at selected source temperatures and selected surface temperatures.

Certifies: Source materials (samples) have acceptable TMLs and CVCMs. (ASTM E595).

Measures: TML, CVCM and QTG

Every Space Materials Engineer, Surface Physicist, Spacecraft Contamination Engineer and Spacecraft Contamination Effects Analyst looking at outgas testing as a means of meeting the new enhancement to the ASTM E-595 standard test method, known as the ASTM E-1559 test, will undoubtedly be interested to hear about the Vacuum Outgassing/Deposition Kinetics Apparatus, with the acronym “VODKA”, designed to meet the new standard in it’s entirety.

The essential components of the VODKA are QCM sensors and an effusion cell, in which you can heat any material (eg. adhesives and sealants, cable insulation and shrink tubing, conformal coatings, electrical components, electrical shields, films and sheet materials, foams, grease, lubricants, liquids, lacing tape and cord cable ties, laminates and circuit boards, paint, ink, lacquers and varnishes, potting compounds, pre-molded rubbers, elastomers, molding compounds and tapes), and measure its outgassing constituents and rate in a high-vacuum chamber. The VODKA Chamber itself features oil-free pumping with turbopumps and is shielded with LN2 cooled plates.

Through the use of a host computer, operation of the chamber is made almost completely programmable. Prepared materials are subjected to environmental temperatures ranging from 293° to 425°K in an effusion cell. Three (or more) CQCMs, set at various distinct temperatures (ranging from 90° to 400°K, for collecting the mass evolved), are placed at 150 mm distance from the cell. Interlock chamber loading of the effusion cell makes the process of changing the source material possible without having to bring the main chamber up to atmospheric pressure (and temperature). The chamber and its various components operate by means of pneumatics. The QCMs and the effusion cell are under the control of a Model 2000 Controller. A mass spectrometer (1-1000 AMU, for RGA) and UV lamps (Krypton, for polemerization of outgassed products) are available as options.

Materials Outgassing

- Prepared materials are subjected to environmental temperatures in the effusion cell

- Effusion cell temperatures range from 293°K to 425°K.

The VODKA makes use of a very small CQCM model. With the case held at 293°K and using the internal heater, the crystals may be raised to 400°K with a heat dissipation of only 0.75 watts. The advantage to this is that you can now do QCM Thermogravimetric Analysis (QTGA) to get condensation information. This unit has a Silicon Diode for sensing the crystal temperature and a hybrid chip residing inside. It has a dynamic range of greater than 8.39 x 10 -4 grams. Either 10 or 15 MHz versions are available. The resolution is ~4×10-2 ng/cm2-s.

TML Measurements

Typical Total Mass Loss and Outgassing Rate measurement QCM at 90°K and at a given material source temperature.

Total Mass Loss (TML):

The prepared material total mass loss at a set source temperature is deposited by known molecular flux onto the coldest (90°K) QCM. The QCM responds to the collecting mass as a frequency shift with test time. This shift can be related to the mass loss percentage and by differentiation, the evaporation rate.

CVCM Measurements

Typical Collected Volatile Mass Loss given by QCM at various temperatures.

Collected Volatile Condensable Materials (CVCM):

Setting the temperature of the collecting QCMs individually, the volatile materials portion that is condensable at each receiver temperature can be measured by the QCMs.

You can determine, with various parameters, the TLM (Total Mass Loss), and CVCM (Collected Volatile Condensable Materials) of a subject material with known source temperatures that are equivalent to the temperatures that exist on the spacecraft and various receiver temperatures equivalent to the temperatures existing on a solar panel or some part of a radiator on the spacecraft. You can even include the more subtle manipulations of the spacecraft as it turns into or away from the sun and receives solar thermal radiation on its panels and you can measure the transmission or the reevaporation of the subject gasses. If your interest involves the polymerization of outgassed products or the effects of UV on subject surfaces, you will be interested in the optional Krypton lamps.

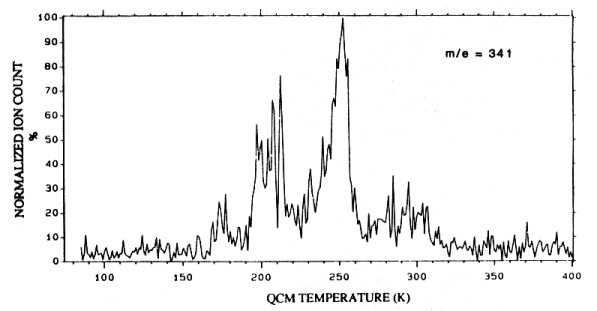

QTGA Measurements

The QCM Model 2000 Controller enables the heating rate to be set. QCM frequency can be read to 0.01 Hz.

QCM Thermogravimetric Analysis (QTGA):

QCMs can be used to identify the molecular species with the VODKA. Use of an in-situ heater in each QCM allows the reevaporation of the deposited mass sequentially with the temperature, and thus the identification from vapor-pressure characteristics.

One of the most important attributes of the VODKA is the ability to do QTGA, that is, QCM Thermal Gravimetric Analysis. Collecting the emitted gasses on quartz crystal microbalances (QCMs) at various temperatures gives a real-time picture of the nature of the constituents. After receiving all of the collected mass on the QCM from the subject material, you can then analyze the deposit by two methods; either with a mass spectrometer accompanied by heating the QCM at a known rate, or by heating the QCM (at a specific rate) and at the same time measuring the frequency change resulting from the removal or re-evaporation of the deposited layer. Then integrating the frequency gives the rate of change, resulting in spikes at specific partial fractionalization points. From these results you can determine the outgassing rate of the molecular constituents of the subject material with temperature, which is a great thing to have knowledge about on a subject material that may outgas for years in an environment virtually impossible to get to.

Mass Spectrometer

Further identification of the evaporating molecular species can be attained by using the Mass Spectrometer and measuring the evolving mass spectrum over a selected m/e scan range (1-1000 amu) and the ion count for each m/e value in this range.

The mass spectrometer controller will provide full scan and time programmed selected ion monitoring modes, variable dwell times, total and selected ion chromatograms, mass spectra and spectrum averaging, background subtraction, mass/intensity lists, X?Y axis scale expansion, library search, and much more. This is a complete mass spectrometer interface and communications controller package.

The basic VODKA Unit (Part Number 81-1562-01) includes the chamber and all necessary support equipment and controllers, an effusion cell, three Mark 18 CQCMs, a Model 2000 Controller and Software. A mass spectrometer (1-1000 AMU, for RGA) and UV lamps (Krypton, for polymerization of outgassed products) are available as options.

Add device Specifiaction tables here.

Warranty

QCM Research products are warranted for a period of ONE YEAR from the date of receipt by the purchaser against defects in materials and workmanship. QCM Research expressly limits its liability to the replacement or repair of the article furnished (this choice is at the sole discretion of QCM Research). This warranty does not apply to products that have been disassembled, modified or subjected to conditions exceeding the applicable product specifications and ratings. In the event of any of the foregoing, the warranty will be void. Failure due to excessive contamination is not covered under warranty, whether from proper or improper use. QCM Research disclaims any warranty other than as specifically set forth herein, and may discontinue models or alter their specifications without notice.